GIVING CUSTOMERS THE CONFIDENCE TO USE RECYCLED AUTO PARTS

Giving customer’s confidence in the parts they are buying, and the business selling them, is essential in increasing the acceptability & use of ‘recycled auto parts’. This doesn’t necessarily mean that the parts are free from damage or that damaged parts can’t be sold - it just ensures that the parts are accurately described, so the buyer understands exactly what they are purchasing, before they purchase. It’s all about managing expectations.

Charltons Recycled Autoparts uses the parts standards developed by the Automotive Recyclers Association of America (ARA) which has helped to make the use of ‘recycled parts’ the ‘norm’ in the USA. The ARA standards are increasingly being used in the UK.

There are ARA standard descriptions for:

- Body panels

- Alloy wheels

- Mechanical parts

BODY PANELS

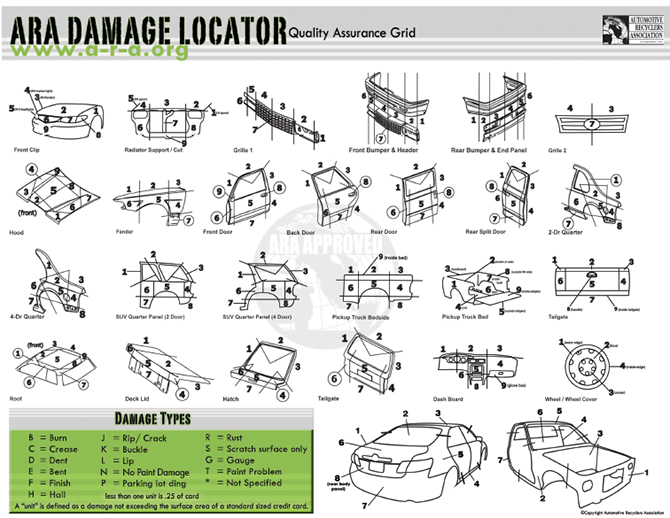

The condition of body panels is described using a simple 3-digit code, which identifies the position, type & extent of damage. Here’s how it works in simple steps:

- Step 1. Using the chart below, pick the code that corresponds to the area of damage. So if you have a door with damage in the centre area of the panel then the first character of your code is ‘5’.

- Step 2. Select from the list the type of damage. So, for example, if the door has a small ‘parking lot ding’, then P is your second character of your code.

- Step 3. Decide the extent of the damage. This is measured in ‘units’ where each unit is defined as damage not exceeding the surface area of a standard sized credit card. So if the damage is less than 1 unit, your final code will be 5P1. However, if it takes two credit cards to cover the damage, the code is 5P2. Clearly, if there is no damage to the panel/ wheel then the code is 000.

Please click on the image above to download the PDF

The ARA code can also be used to price parts.

WHEELS

Used wheels are ‘graded’ in the same way, using the 3-digit code.

- Step 1. First they are visually inspected. Any wheels with cracks & distortions are scrapped. No hammering, straightening or reforming of wheels should be undertaken.Undamaged wheels are ‘graded’ according to whether they have any minor surface ‘blemish’:

- Grade A: wheel has no blemish

- Grade B: wheel has a ‘1 unit’ blemish (area of blemish is smaller than a credit card)

- Grade C: wheel has a blemish of more than one unit of damage

- Step 2. Wheels that have defects/ damage are then graded using the area codes:

- 1 Outside edge

- 2 Face

- 3 Centre

- 4 Inside edge

- Step 3. They are then inspected for minor damage that cannot be corrected by sanding or polishing, including:

- Corrosion (damage code R)

- Scuff-scrape (damage code S)

- Gouge (damage code G)

- Dents (damage code D)

- Paint/ lacquer problem (damage code T)

So, a wheel with a surface scrape the size of 2 credit cards could be described as condition ‘2S2’ (damage location, type of damage, extent of damage).

MECHANICAL PARTS GRADING

Mechanical parts are graded according to total mileage or average miles per year, as follows:

- Grade A: less than 60,000 miles, or if over 60,000 miles, less than an average of 15,000/ year. For example, a vehicle of any age with 55,000 miles in total, or a 10 year old car with only 85,000 miles (8,500 miles pa average)

- Grade B: 60,000- 200,000 miles in total on them, regardless of age. Also any vehicle >60,000 miles in total where the average miles pa >15,000 miles.

- Grade C: have equal to or greater than 200,000 total miles on them regardless of age.